- AUTO CONNECTOR AUTOMATIC ASSEMBLY MACHINE PROFESSIONAL

- AUTO CONNECTOR AUTOMATIC ASSEMBLY MACHINE SERIES

Robotic Assembly for I-PEX Connectors / Panasonic Parallel Link Robot

AUTO CONNECTOR AUTOMATIC ASSEMBLY MACHINE SERIES

The ES- Gripper can handle different types of connector series such as FPC/FFC connectors, wire-to-board, board-to-board, and any other connector types by using a customized attachment head design.Ĭheck out these videos showing a collaborative and industrial robot that mates FPC to I-PEX Connectors. The ES-Gripper integrates a torque sensor (ESTORQ) for detecting connector insertion force and data recording as the tractability for big data/AI analysis, which helps improve productivity and efficiency.

AUTO CONNECTOR AUTOMATIC ASSEMBLY MACHINE PROFESSIONAL

The I-PEX ESTORQ ® Sensor’s torque sensor technology was incorporated into the ES-Gripper for the purpose of automatic insertion for connectors. Various products of Auto connector assembly machine, providing product images and basic parameters with each car connector assembly, vechicle connector assembly,automobile connector assembly,automotive connector assembly, cars connector assycars connector assembly We are a professional Chinese manufacturer of automotive connector assembly mach. This can eliminate human factors, reduce labor cost, learning curve, tact-time, raise quality, speed, reliability, and create connector assembly machine by connector supplier.ĭai-Ichi Seiko Group, which includes the core technologies of fully-automated machines, sensors ad connector developments, is the only company that can provide a total solution for customers in the automation industry: design, produce, integrate connectors, sensors, fully-automation machine technologies. Contributes to Assembly automation as a Automation Connector. The Blue Ocean Strategy: In order to solve this headache and increase manufacturing productivity, phasing-in robotic automation is the ideal solution. We are doing a demonstration to assemble the actual PLC machine.

When operator errors happen, the only choice they have is to scrap the whole PCB, including the components already mounted on the PCB.

We are a high-tech factory devoted ourselves to automation industry for 12+ years.

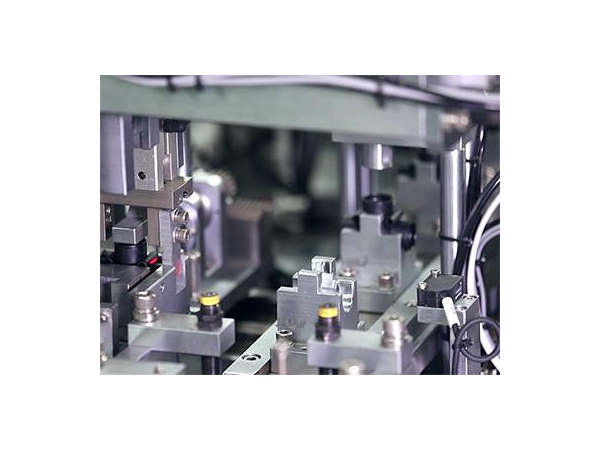

Machine can achieve feeding, bending, assembling and detection automatically. Unfortunately, some industries, like automotive, do not allow any re-work process due to their "Zero Defect" policy. Automatic Connector Pin Inserting Assembly Machine is specially designed and manufactured for automobile connectors production industry. The objective is to create and develop an automated inspection system used to sort the water connector product after the assembly process. The only way to repair the damaged connectors is by completing a re-work process on the PCB and the connectors, one-by-one, manually.Ĭorrecting the “human factor” in factories by doing re-work wastes a lot of time and money. There are many elements that need to be carefully controlled by the operators manually. Large touch screen monitor: 10.In the past 20 years in the IT industry, the major complaints received from customers are not product quality issues, but operational issues (more than 30%). These issues are due to the human factor, meaning that operators unintentionally damaged the connectors due to an uncontrollable angle, direction, location, handling force, speed, tact-time, lack of training, etc. We also offer the development of unique heads and tooling specifically for your project. Our modular pin insertion head technology allows for quick application tooling changeover and maintenance. We carry more than a dozen of various insertion heads designed for each component. Small but powerful, the MicroSert system inserts up to three components per second and is built for today’s fast-paced global manufacturing environment. Its design allows one operator to run two machines simultaneously which significantly increases the production efficiency.Ī single head stand-alone base incorporates a 12”x12” (304mm x 304mm) insertion area and is digital servo motor driven. The Klippon® Automated RailAssembler enables fully automated assembly of terminal strips.

0 kommentar(er)

0 kommentar(er)